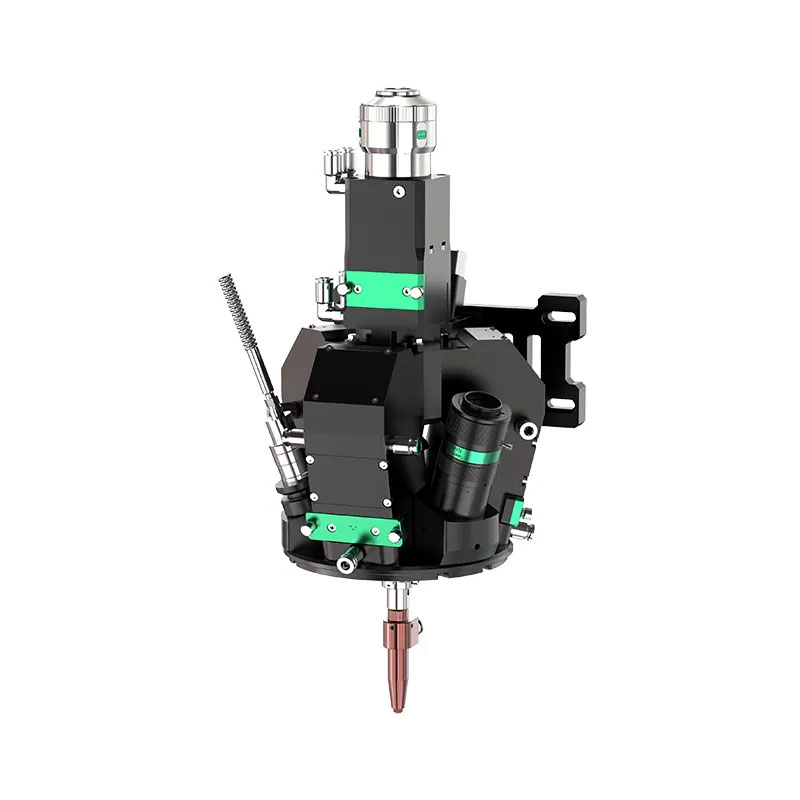

The BP06K is not a traditional

Marking Machine, but a coaxial wire-feeding laser head that brings "

Laser Marking Machine-level" beam precision to cladding/repair applications. The incident laser is split into three 120° symmetrical "light fingers," coaxially wrapping the welding wire along a conical path, achieving an energy uniformity of ±2%—equivalent to upgrading the "single-point impact" of a

Dot Peen Marking Machine to a 360° annular "light forging," while retaining the high efficiency of a

Pneumatic marking machine in a single pass, and reducing spatter by 60%.

Advantages and Highlights

?

- High Cost-Effectiveness: The number of optical path components is only 70% of that of imported heads, reducing procurement costs by 30%; its compact Φ62 mm × 185 mm size can be directly integrated into the Z-axis slide of existing Laser Marking Machines, allowing marking in the morning and cladding in the afternoon without the need for additional robots.

?

- Three-beam coating: The filament is uniformly melted by the "light cone," with directional sensitivity 50% lower than that of a coaxial powder head. The repair layer thickness is adjustable from 0.5 to 2 mm, and the hardness uniformity error is < ±15 HV. This replaces the cold-working welding of traditional dot-peen marking machines, resulting in no porosity or cracks.

?

- 360° annular air knife: Smoke and spatter are instantly blown away by the "light wall," increasing the lifespan of the protective

Lens from 48 hours to 120 hours, far exceeding the frequency of cleaning required per shift for nozzles of pneumatic marking machines due to metal dust clogging.

?

- Direct water cooling + modular interface: The temperature difference of key lenses is < 3 ℃, and the thermal lensing effect is negligible. A CCD and closed-loop temperature measurement slot is reserved on the side, allowing the "visual positioning-temperature feedback" algorithm commonly used in marking machines to be directly transplanted into the cladding process, achieving "melting, measuring, and controlling simultaneously."

?

Application Approaches

?

- High-Value Shaft Repair: Under a 6 kW laser, the BP06K laser deposits a 1 mm stainless steel layer on the wear area of ??a 42CrMo crankshaft. No subsequent annealing is required; the same machine can be used to directly switch to low-power Laser Marking Machine mode for on-the-fly marking of traceability codes, completing "repair + marking" in a single setup. This reduces cycle time by 40% compared to offline

Dot Peen Marking Machines.

?

- Mold Surface Strengthening: H13 hot forging die cutting edges are clad with a cobalt-based alloy, increasing hardness from 45 HRC to 58 HRC and extending lifespan by 3 times. The coaxial wire feeding path can follow 3D curved surfaces with curvature radii as small as R50 mm, replacing the "multi-pass grinding" cycle of manual Pneumatic marking machine welding.

?

- Aerospace Blade Remanufacturing: A wear-resistant coating is clad onto the titanium alloy blade tip with a thickness tolerance of ±0.05 mm. No further machining is required; the blade directly proceeds to the Marking Machine unit for DataMatrix engraving, achieving a closed loop of "cladding-coding-delivery"—all laser-based with zero mechanical contact.

?

Overview: The BP06K utilizes a three-beam coaxial concept, integrating the micron-level energy control of the Laser Marking Machine, the graphic trajectory freedom of the Marking Machine, the local enhancement depth of the Dot Peen Marking Machine, and the high deposition efficiency of the Pneumatic Marking Machine into a single laser head weighing only 1.4 kg. Whether repairing a 5 mm small gear or remanufacturing a 2 m marine crankshaft, simply access the "cladding-marking" dual-process package on the touchscreen. Wire replacement and head-mirror calibration are completed in 2 minutes, allowing the same laser to perform cladding followed by marking—using a single BP06K, the remanufacturing workshop and traceability station are merged into a highly flexible, zero-rebound "

Laser Cladding + laser marking" composite production line.